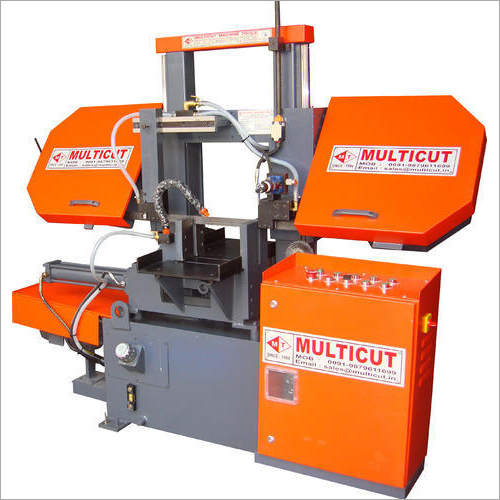

Connecting Rod Cutting Machine

Product Details:

- Drive Motor 3 HP

- General Use Industrial

- Weight (kg) 1200 Kilograms (kg)

- Automatic Yes

- Control System PLC Control

- Cutting Speed 15 - 90 mm/s

- BladeSize 4100 x 34 x 1.1 mm

- Click to view more

Connecting Rod Cutting Machine Price

- 500000 INR/Piece

- 1 Piece

Connecting Rod Cutting Machine Specification

- 1 Year

- Electric

- 15 - 90 mm/s

- Industrial

- PLC Control

- 1200 Kilograms (kg)

- 4100 x 34 x 1.1 mm

- 3 HP

- Yes

Product Description

This high performance Connecting Rod Cutting Machine deserves praise for its user friendly mechanism. This equipment comprises of 4100 x 34 x 1.1 mm blade that can maintain 15 to 90 mtr cutting speed per minute. It also consists of gear box with 3 l oil storage capacity, 0.5 HP hydraulic motor, 10 l hydraulic tank and 3 HP main drive motor. Provided Connecting Rod Cutter requires 3.64 HP power to function and its net weight is around 1200 kg. Its cutting tolerance is +0.2/100 mm.

A connecting rod cutting machine is a specific piece of hardware used to cut and shape connecting rods, which are urgent parts in gas powered motors. Connecting rods interface the cylinder to the driving rod, changing over straight movement into rotational movement. These machines are utilized in car, flying, and different ventures that require accuracy motor parts.

Advantages of Connecting Rod Cutting Machine:

- Exact and reliable cuts for ideal motor execution.

- Productive handling for excellent connecting rods.

- Decreased difficult work and administrator exertion.

- Might the machine at any point deal with various sizes and kinds of connecting rods?

- Many connecting rod cutting machines offer customizable elements to oblige different rod sizes, lengths, and shapes.

Connecting Rod Cutting Machine Specification:

- Blade Size: 4100 x 34 x 1.1 mm

- Power: 3.64 HP

- Net Weight(Approximate): 1200 Kg

- Main Drive Motor: 3 HP

- Hydraulic Tank Capacity: 10 L

- Hydraulic Motor: 0.5 HP

- Gear Box Oil Capacity: 3 L

- Cutting Tolerance for En-8 Round: +- 0.2 / 100 mm

- Cutting Speed: 15 - 90 mtr /min

- Cutting Capacity: 300 mm (Round) and 320 x 300 mm (Square)

- Coolant Tank Capacity: 25 L

- Coolant Motor: 0.14 HP

FAQs of Connecting Rod Cutting Machine:

What is a connecting rod cutting machine utilized for?

A connecting rod cutting machine is utilized to cut, shape, and complete the process of connecting rods, guaranteeing exact aspects and ideal execution in gas powered motors.

How does a connecting rod cutting machine work?

The machine utilizes cutting apparatuses, for example, grating wheels or processing cutters to precisely cut and shape the connecting rod spaces.

What kinds of connecting rods can be handled utilizing a connecting rod cutting machine?

Connecting rod cutting machines are intended for different sorts of connecting rods utilized in various motor arrangements, for example, inline, V-type, and fighter motors.

What wellbeing highlights are ordinarily remembered for a connecting rod cutting machine?

Wellbeing highlights might incorporate watchmen, crisis stop buttons, defensive walled in areas, and security interlocks to guarantee administrator wellbeing.

Is preparing expected to work a connecting rod cutting machine?

Indeed, appropriate preparation is fundamental for protected and productive activity. Administrators ought to be prepared on machine arrangement, activity, support, and wellbeing conventions.

Might the machine at any point be modified for explicit cutting errands?

Some connecting rod cutting machines might offer programmable highlights for exact and repeatable cutting assignments, particularly in further developed models.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese